Calcination of the limestone is done continuously in the vertical kiln. It is a chimney-like structure having an outer diameter of 10 – 24 feet & a height of around 55 – 75 feet.

It has stainless steel outer lining fitted with refractory material.

Fixing of the kiln is carried out using burning coal or use of gaseous fuel (natural gas) heated inside the fire brick.

The calcination of limestone particles of size 6 – 8 inches can be carried out using a vertical field.

Most of the vertical kiln is fixed using the burners of natural gas.

The current of cold air is passed at the bottom which helps to crystallize quick lime at the bottom and also expel CO2, hence prevent reverse reaction

Finally, the quicklime is collected in the trolley running under the furnace

Applications:-

Binding material in the concrete.

Used for plastering and repairing lime sand bricks and also in cement bricks.

Lime is used as a fixing material in a large number of industrial processes.

Lime is also used in the paint industry.

Lime is also used in the fields to make the soil fertile for agricultural purposes.

Used for purification of water and in wastewater treatment.

Also used as a fixing agent in the paper industry

In the refining, the sugar and other food industry lime are most commonly used.

In the vertical kiln,

the material moves from top to bottom, and the combustion air moves from bottom to top.

The heat carried by the high-temperature materials preheats the combustion air.

The process is reasonable, the heat loss is small, and the discharge temperature can be controlled within the temperature of +60℃, the thermal principle is reasonable.

The disadvantage of the traditional vertical kiln is the poor combustion conditions because the internal calcination of the cake and large pellets is lack of oxygen and result in incomplete combustion.

With the continuous progress of technology, such as further improvement of batch control, the strengthening of raw material homogenization, the improvement of kiln type structure and air supply method, and the small material ball greatly reduces the moisture content of the material ball.

The heat consumption of clinker in modern shaft kiln can be controlled within (600 ~ 700) × 4.18kj.

It belongs to the equipment with high thermal efficiency.

What Is Shaft Kiln?

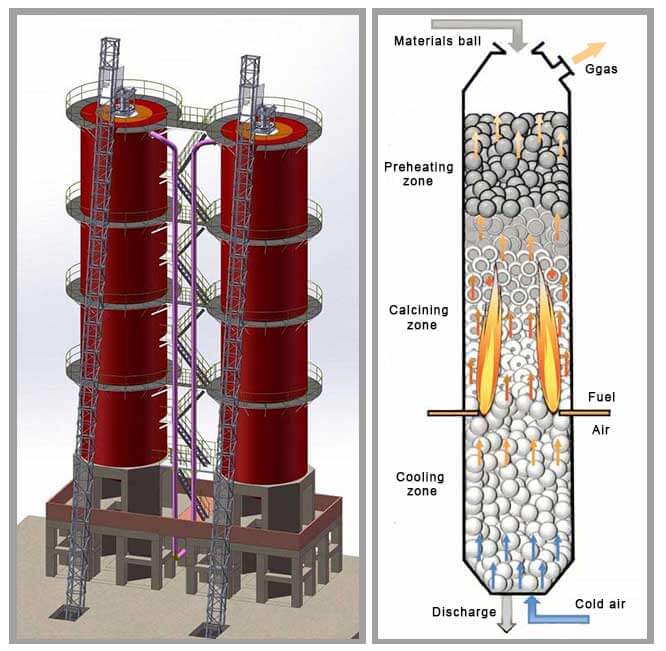

Shaft kiln, also called vertical shaft kiln or vertical kiln, is a kind of vertical set stationary cement kiln; usually applied in the cement production line, lime production line, etc.

As one of the main cement equipment, it plays the same role as a cement rotary kiln for cement clinker manufacturing, also composed of preheating zone, calcining zone, and cooling zone, while no matter the production process, investment, or cement properties, it is different from the rotary kiln.

The shaft kiln can be divided into ordinary shaft kiln and mechanical shaft kiln according to different operation modes. The mechanical shaft kiln can be operated continuously, and its production quality and productivity are relatively high, which has been widely used in mini cement plants.

How Does Shaft Kiln Work?

Before calcination, raw materials will be mixed with coal powder to form raw material balls. They enter the shaft kiln from the kiln crown and gravity flow through three thermally sections respectively the preheating zone, calcining zone, and cooling zone. During these processes, the raw meal balls will be heated from ambient temperature to more than 1000℃ by a countercurrent flow of hot air rising from the kiln burner so that the coal powder on the surface or inside burns one after another and the raw meal can finally transfer into clinker.

Preheating Zone. This area is mainly used to dry, preheat and pre-decompose the material balls. In general, it will account for 10% – 15% of the whole kiln body height. After materials are calcined, the remaining hot air will rise to the preheating zone to preheat materials to a pre-decomposition temperature.

Calcining Zone. This area is a high-temperature area that calcines materials through hot air released from the burner. The residence time of materials in the calcining zone shall not be too long or too short, generally 25 minutes, so as to ensure the cement meal can have sufficient chemical reaction.

Cooling Zone. The cooling zone is located between the calcining zone and the kiln bottom. In this area, the clinker exchanges heat with the cold air blown from the kiln bottom so as to cool down the clinker temperature, meanwhile, the cold air is heated and then enters the calcining zone as an oxidizing air.

Comments

Post a Comment